solcudi® seals: references + results

Our patented solcudi® technology has been developed in close cooperation with leading universities and independent research institutes. From the very beginning, our core principle has been to bring to market only sealing solutions that are comprehensively tested, validated, and proven under real operating conditions.

Today, solcudi® seals are officially series-approved and supplied in serial production to multiple international OEMs. These approvals are the result of extensive internal bench testing, external validation programs, and long-term field operation, confirming both performance and reliability at an industrial scale.

In parallel to ongoing serial supply, additional global OEMs are currently conducting approval programs, endurance tests, and field trials with solcudi® seals. These activities underline the growing adoption of the technology and our continuous expansion across demanding applications and markets.

While specific project details remain confidential due to contractual agreements, we can confirm that solcudi® seals are operating worldwide in applications such as mining trucks, construction machinery, underground mining equipment, and other high-demand applications. To date, several thousand field operating hours have been successfully accumulated under real-world conditions.

The following table highlights selected examples of current field operating hours:

,,,

| application | solcudi® seal Ø | acc. operating hours | status | remark |

|---|---|---|---|---|

| large mining trucks | 450–700 mm | 48,400 (as of Dec 2025) | surpassed lifetime of conventional seals by 18% – still running flawlessly | some trucks run under highly demanding conditions – increased speed and elevated oil temps |

| ultra-large mining trucks | 700–1,200 mm | 31,400 (as of Dec 2025) | in operation | installation process optimized. Conventional seals previously caused misalignment and cracks |

| dozers | 100–550 mm | 18,450 (as of Dec 2025) | surpassed lifetime of conventional seals by 12% – still in service | no leakage observed; high wear / mud-packing application |

| large mining excavators | 500–1,200 mm | 17,300 (as of Dec 2025) | in operation | reliable operation – no issues to date |

| wheel loaders | 100–400 mm | 33,000 (as of Dec 2025) | in operation | reliable operation – no issues to date |

| underground mining equipment | 300–600 mm | 47,500 (as of Dec 2025) | in operation | reliable operation – no issues to date |

| trench cutter | 450–650 mm | 23,900 (as of Dec 2025) | > 3× lifetime of conventional seals | extreme wear & corrosive application – no issues to date |

These and other field results clearly demonstrate what our internal testing has confirmed with precision:

solcudi® seals offer unprecedented performance advantages over conventional high-quality cast iron seals.

The next section provides deeper insights into our in-house testing methodology highlighting the full potential of solcudi® sealing technology under extreme operating conditions.

FUNCTIONAL TESTING

Every seal we develop undergoes thorough testing before being released for production. Additionally, we regularly conduct random test runs to verify and maintain our high-quality standards. Our typical test is a functional test, where we primarily check and evaluate:

- leak-tightness

- friction coefficient

- adhesion properties (scoring resistance)

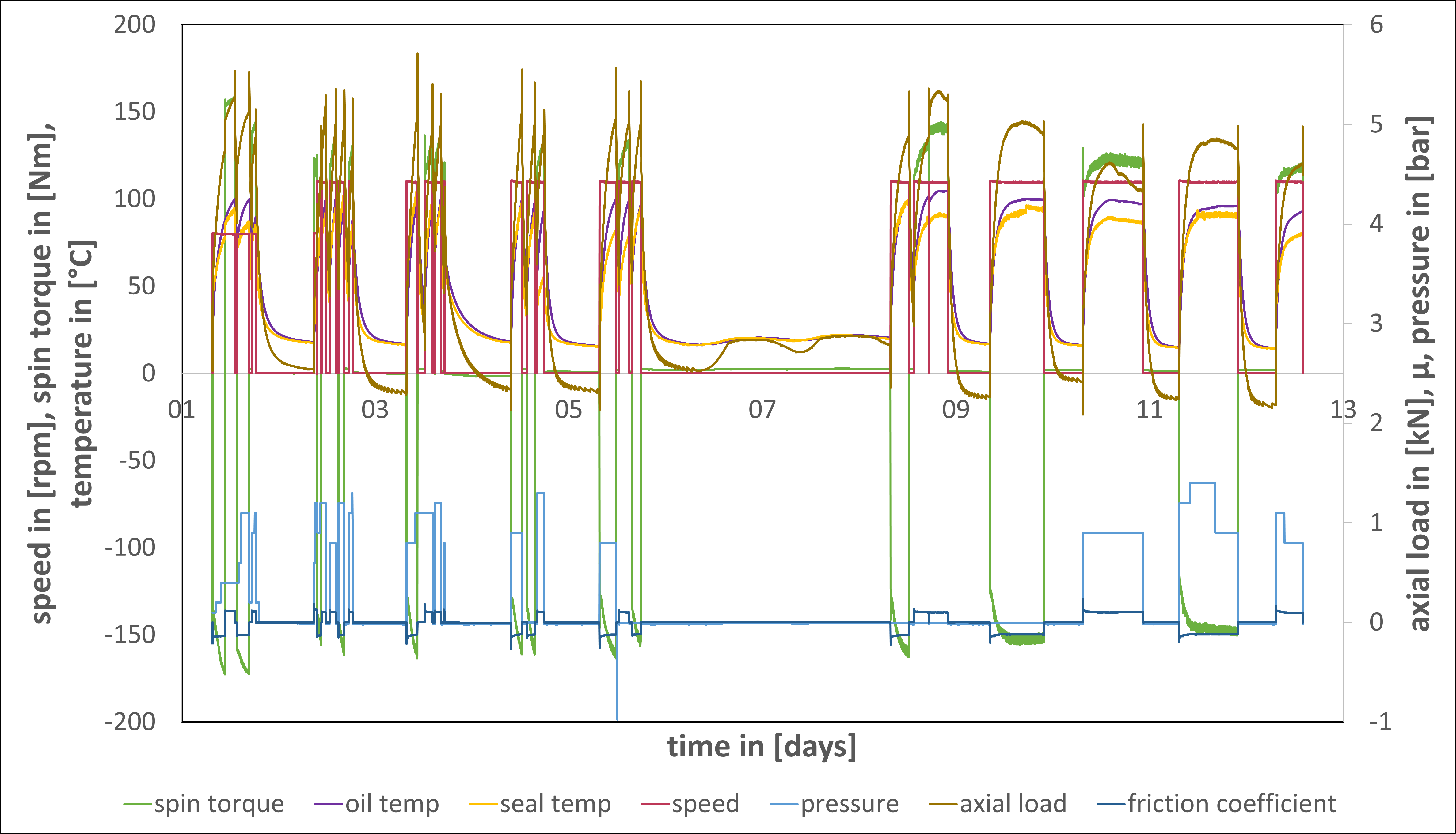

The diagram shows typical recorded data for a large ∅ 850mm (32″) solcudi® PC75 seal over a 100-hour test run at 110 rpm, demonstrating perfect tightness. The corresponding test run can be seen in the video clip below.

CORROSION TESTING

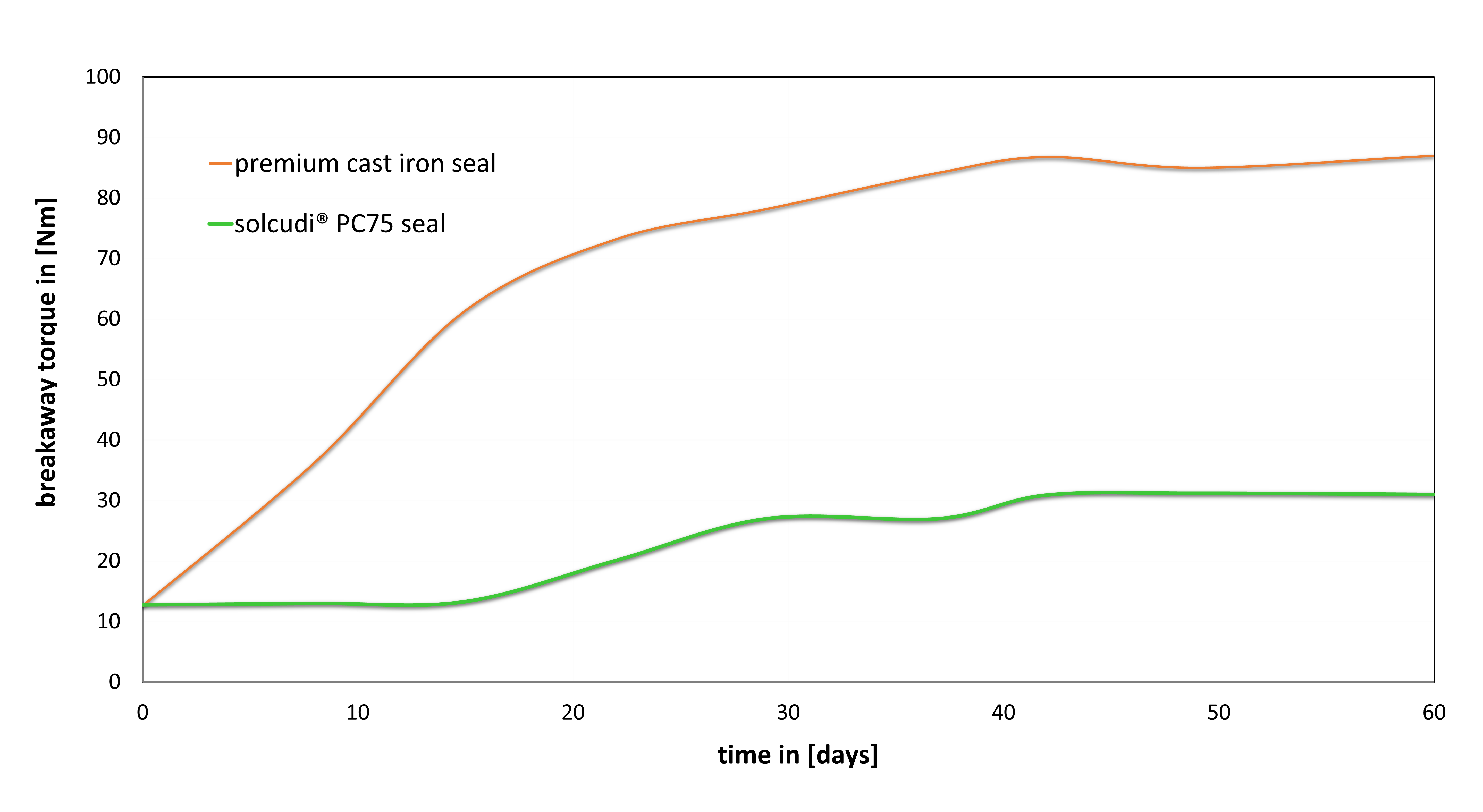

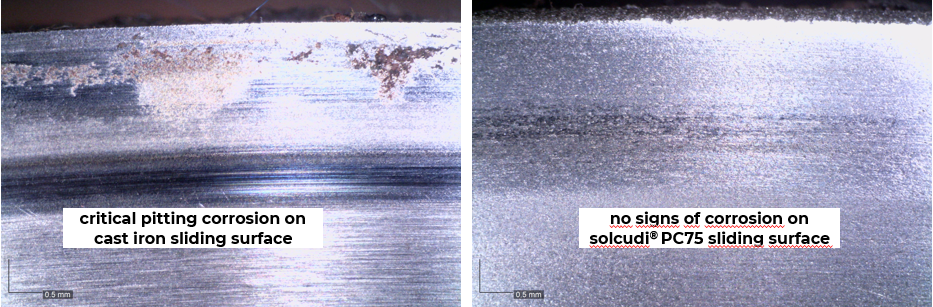

With our unique corrosion test, we can assess the performance of a seal set in an installed condition, similar to its actual application. The seal operates for 24 hours to achieve a running-in condition. Afterwards, it is exposed to a corrosive environment (high humidity and warm atmosphere) for several weeks. Each week, the breakaway torque is measured and documented. The diagram shows the typical breakaway torque curve for a premium / high-quality cast iron seal compared to a solcudi® seal. The latter exhibits approximately 3 times lower breakaway torque. As a result, the solcudi® seal maintains its outstanding sealing capabilities, while the premium cast iron seal shows significant leakage. This leakage is due to small pits on the sliding surface caused by corrosion. Solcudi® seals, however, maintain their smooth surface structure and remain perfectly tight. This fact is particularly crucial for applications that can stand idle for a longer period of time.

WEAR TESTING

To validate durability and reliability, we operate several custom-built wear test rigs that simulate the toughest real-world conditions. Seals are mounted in their actual installation configuration and run for a defined extended period.

An abrasive medium – such as mud or dry Arizona dust – is introduced into the mudbox where the seal operates continuously. Possible testing conditions can be seen in the video clips below. Two critical performance indicators are assesed:

- Leak-tightness throughout the test cycle

- Material wear on both seal rings, precisely measured and documented

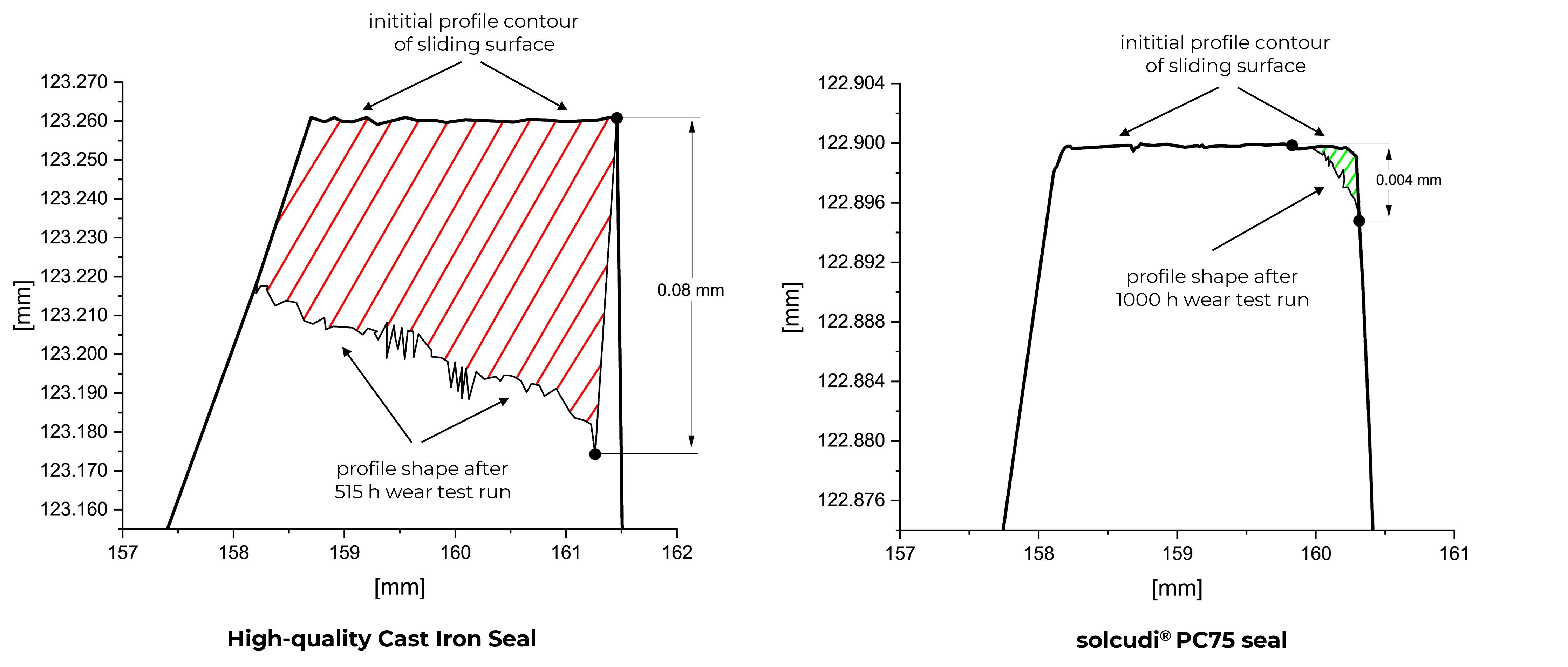

Comparison of Wear Characteristics – Cast Iron vs. solcudi® PC75

The diagrams show comparative profilometric measurements of the sealing face / sliding surfaces from a premium / high-quality cast iron seal and a solcudi® PC75 seal, both Ø119 mm (4.7″), after identical test runs at 250 rpm.

While the solcudi® PC75 seal maintained perfect leak-tightness and successfully completed the full 1,000-hour test cycle, the cast iron seal failed after just 515 hours due to leakage and exhibited severe wear. The solcudi® solution showed almost no wear, confirming its outstanding resistance under highly abrasive conditions.